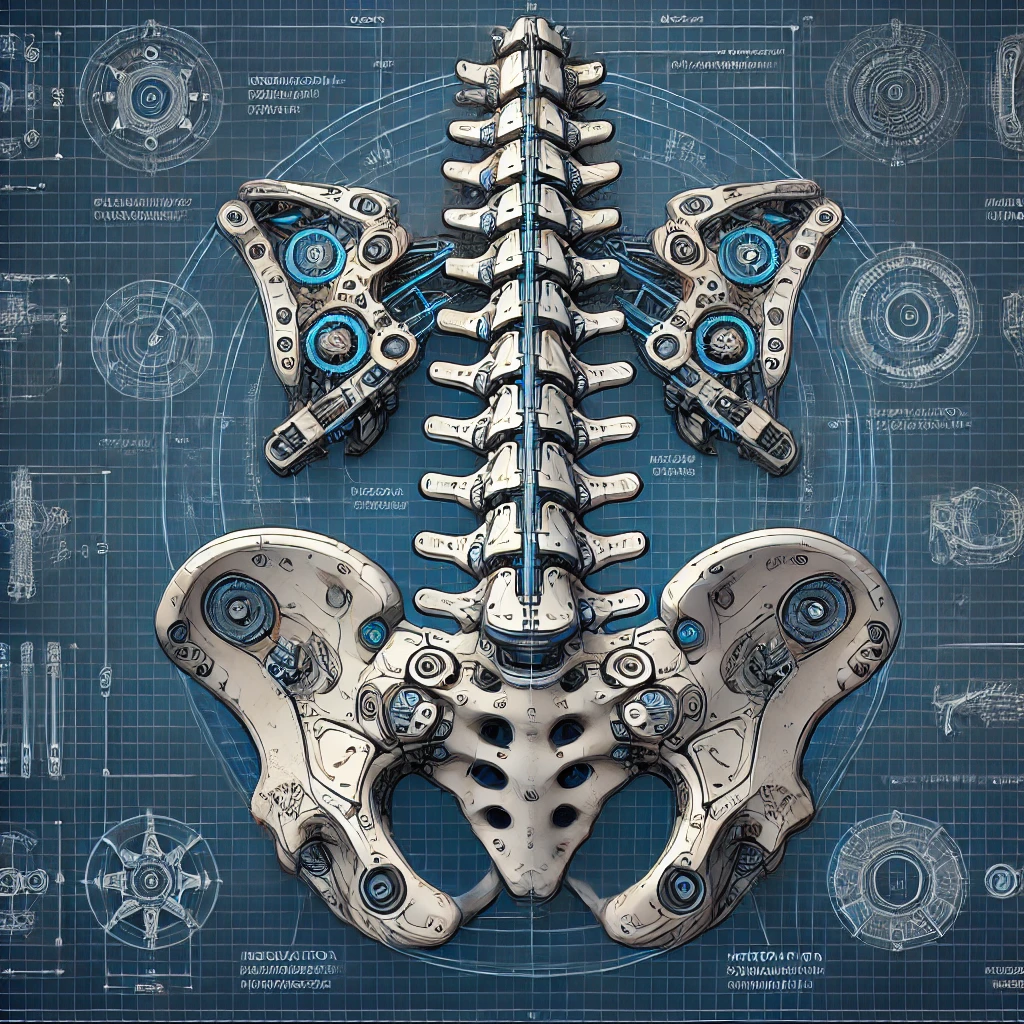

The spine of a humanoid robot serves as the central structural and functional component that connects the head, upper body, and lower body. It mimics the flexibility and functionality of a human spine, enabling the robot to bend, twist, and support dynamic balance. Below is a comprehensive guide for designing a humanoid robot spine and vertebrae.

1. Functional Objectives

The robotic spine must:

- Provide Structural Support: Connect the head, arms, and torso to the legs.

- Enable Flexibility: Allow bending, twisting, and other dynamic movements.

- Ensure Stability: Maintain balance during movement and interaction.

- Distribute Loads: Transfer and distribute weight evenly across the structure.

- House Components: Encapsulate wires, sensors, and actuators safely.

- Provide Feedback: Use sensors to monitor position, torque, and loads for control adjustments.

2. Key Components

| Component | Function |

| Vertebrae Modules | Individual segments providing mobility and housing for components. |

| Intervertebral Joints | Allow controlled motion between vertebrae. |

| Actuators | Drive movement such as bending, twisting, and stabilization. |

| Sensors | Monitor position, torque, and environmental interactions. |

| Frame Structure | Provide the backbone for mounting other components. |

| Shock Absorbers | Dampen forces during movement and external impacts. |

| Power Transmission | Transfer energy efficiently for spinal movements. |

| Cabling Channels | Secure pathways for wires and signal cables. |

3. Degrees of Freedom (DOF)

The robotic spine should mimic the human spine’s movement:

- Flexion/Extension: Forward and backward bending.

- Lateral Flexion: Side-to-side bending.

- Axial Rotation: Twisting left and right.

Each vertebra typically has 3 DOF, with a cumulative effect allowing realistic and flexible motion.

4. Design Process

4.1 Structural Design

- Vertebrae Design:

- Use modular segments for easy assembly and maintenance.

- Incorporate hollow centers to house wires and sensors.

- Materials: Lightweight materials such as carbon fiber or aluminum alloy for strength and weight reduction.

- Intervertebral Discs:

- Use flexible, durable materials (e.g., polyurethane or silicone) to mimic biological discs.

- Provide shock absorption and allow controlled movement between vertebrae.

4.2 Actuation

- Use a combination of actuators to enable spinal movements:

- Servo Motors: For precise angular adjustments.

- Linear Actuators: To control bending and extension.

- Pneumatic or Hydraulic Actuators: For high power and fluid motion.

- Actuation Placement:

- Embed actuators within or alongside vertebrae to save space and distribute weight evenly.

4.3 Sensor Integration

- Encoders: Track angular position and rotation speed.

- IMUs: Monitor orientation and acceleration for balance.

- Force Sensors: Measure loads on the spine for dynamic adjustments.

- Tactile Sensors: Detect external forces for collision detection and feedback.

4.4 Control System

- Central Processor: Use microcontrollers (e.g., STM32, Raspberry Pi) to manage spinal motion.

- Real-Time Feedback: Implement PID controllers for smooth and precise movement.

- Dynamic Balance Algorithms: Use AI to adjust posture and motion dynamically.

4.5 Cooling System

- Passive Cooling: Use heat sinks to dissipate heat from actuators and processors.

- Active Cooling: Add small fans for continuous operation under high loads.

5. Modular Vertebrae Design

Vertebra Components

| Component | Function | Material |

| Vertebra Frame | Structural element connecting other vertebrae. | Carbon Fiber or Aluminum Alloy |

| Intervertebral Disc | Shock absorption and flexibility between vertebrae. | Polyurethane or Silicone |

| Joint Bearings | Enable smooth rotational movement. | Stainless Steel |

| Actuator Brackets | Secure actuators to vertebrae. | Aluminum |

| Cable Channels | Route wires and signal cables through the spine. | ABS Plastic |

6. Example Subsystems

6.1 Actuation System

| Component | Description | Example |

| Servo Motor | Provides precise movement for flexion and extension. | MG996R Servo Motor |

| Linear Actuator | Enables forward and backward bending of the spine. | Firgelli Mini Linear Actuator |

| Rotary Actuator | Drives twisting motions along the axial direction. | Maxon EC90 Flat |

6.2 Sensor System

| Component | Description | Example |

| IMU Sensor | Tracks orientation and angular velocity of the spine. | MPU-6050 |

| Force Sensor | Measures load and torque at key vertebral joints. | ATI Mini45 |

| Rotary Encoder | Tracks angular position of individual vertebrae. | AMT102-V Rotary Encoder |

7. Power and Control

- Power Distribution:

- Use a centralized power bus to distribute energy efficiently to actuators and sensors.

- Ensure proper shielding to avoid electromagnetic interference.

- Control Software:

- Implement ROS or similar frameworks for modular control.

- Use algorithms for real-time posture adjustment and gait synchronization.

8. Integration with Torso and Legs

- Upper Connection: Securely attach the spine to the torso frame for stability and seamless movement.

- Lower Connection: Design a robust joint mechanism to connect the spine to the hip, enabling rotational and bending motions.

9. Challenges and Solutions

| Challenge | Solution |

| Weight and Space Constraints | Use lightweight materials and compact actuators. |

| Smooth Multiaxis Motion | Incorporate high-precision sensors and PID controllers. |

| Load Distribution | Design a robust frame with evenly distributed loads. |

| Heat Management | Use passive and active cooling systems. |

| Signal Integrity | Use shielded cables to prevent interference between sensors and actuators. |

10. Advanced Features

- Dynamic Posture Control: Use AI to adjust the spine’s posture based on external conditions.

- Energy Recovery: Implement regenerative braking in actuators for energy efficiency.

- Adaptive Flexibility: Incorporate algorithms to adjust stiffness or flexibility dynamically.

- Tactile Feedback: Add tactile sensors to enhance environmental interaction.

11. Tools and Software

- Design Tools: SolidWorks, AutoCAD, Fusion 360 for mechanical design.

- Simulation Tools: MATLAB/Simulink, Gazebo for motion analysis and gait testing.

- Programming Frameworks: Python, C++ with ROS for system integration.

Conclusion

A humanoid robot spine and vertebrae are essential for mimicking the flexibility and motion of a human body. By integrating advanced materials, actuators, sensors, and control systems, the robotic spine can provide structural support, realistic movement, and dynamic adaptability for various tasks and environments.