Testing humanoid robots for safety is a critical step to ensure they can operate without posing risks to humans, the environment, or themselves. These tests evaluate mechanical, electrical, software, and interaction safety, adhering to international standards and best practices. Here’s an overview of how humanoid robots are tested for safety:

1. Mechanical Safety Testing

Purpose: Ensure structural stability, physical durability, and safe interactions.

Tests Conducted:

- Stress and Load Testing:

- Simulate forces applied to joints, limbs, and frames under various conditions.

- Verify the robot’s structural integrity during repetitive or extreme movements.

- Range of Motion Testing:

- Confirm joints operate within safe limits using physical stoppers.

- Test for excessive speed or unexpected movements.

- Impact Force Testing:

- Measure the force generated during accidental collisions or interactions with humans.

- Ensure compliance with force limits (e.g., ISO/TS 15066 for collaborative robots).

- Balance and Stability Testing:

- Evaluate the robot’s ability to maintain balance while walking, standing, or during dynamic tasks.

- Use tilting platforms or uneven surfaces to test stability.

- Fatigue Testing:

- Test components for wear and tear under repetitive motions (e.g., walking cycles).

- Identify potential failures over the robot’s operational lifespan.

2. Electrical Safety Testing

Purpose: Prevent hazards like electric shocks, short circuits, and overheating.

Tests Conducted:

- Insulation Resistance Testing:

- Measure insulation effectiveness to prevent electric shocks.

- Grounding and Earthing Tests:

- Ensure proper grounding to avoid static buildup or electrical leakage.

- Overload and Overvoltage Protection Testing:

- Simulate power surges and test the effectiveness of circuit breakers or voltage regulators.

- Battery Safety Testing:

- Evaluate battery performance under normal and extreme conditions.

- Test for overheating, overcharging, or explosion risks.

3. Software Safety Testing

Purpose: Ensure the robot’s software behaves predictably and handles failures gracefully.

Tests Conducted:

- Functional Testing:

- Verify the robot executes programmed tasks without errors.

- Test edge cases to assess behavior under unexpected inputs.

- Fail-Safe Mechanisms:

- Simulate failures (e.g., sensor malfunctions or power loss) to ensure safe recovery or shutdown.

- Confirm emergency stop buttons function effectively.

- Redundancy Testing:

- Verify backup systems maintain control during primary system failures.

- Real-Time Performance Testing:

- Ensure software processes inputs and generates responses in real time without significant delays.

4. Interaction Safety Testing

Purpose: Ensure safe and predictable behavior during human-robot interactions.

Tests Conducted:

- Collision Detection:

- Test sensors (e.g., LiDAR, ultrasonic) for accurately detecting obstacles or humans.

- Evaluate response time for stopping or rerouting after detection.

- Tactile Safety Testing:

- Assess touch sensors for responsiveness to physical contact.

- Simulate accidental interactions to ensure the robot reacts safely.

- Proximity Detection:

- Test range and accuracy of proximity sensors to avoid unsafe movements near humans.

- Behavioral Testing:

- Evaluate the robot’s responses to human gestures, commands, or unexpected behavior.

5. Environmental Safety Testing

Purpose: Verify the robot’s ability to operate safely in diverse environments.

Tests Conducted:

- Temperature and Humidity Testing:

- Expose the robot to extreme temperatures and humidity levels to test operational reliability.

- Dust and Water Resistance Testing:

- Evaluate ingress protection (IP) ratings for resistance to dust and water.

- Electromagnetic Compatibility (EMC):

- Test for compliance with electromagnetic interference (EMI) standards to avoid disrupting or being disrupted by nearby devices.

- Drop and Shock Testing:

- Simulate accidental falls to assess structural damage and recovery.

6. Cybersecurity Testing

Purpose: Protect the robot and its users from malicious attacks or data breaches.

Tests Conducted:

- Penetration Testing:

- Simulate cyberattacks to identify vulnerabilities in the robot’s software or network.

- Encryption Testing:

- Verify data encryption for secure communication between the robot and external systems.

- Access Control Testing:

- Ensure only authorized users can control or modify the robot’s settings.

7. Ethical and Behavioral Safety Testing

Purpose: Ensure the robot adheres to ethical guidelines and promotes safe interactions.

Tests Conducted:

- Bias Detection:

- Evaluate AI algorithms for potential biases in decision-making or interactions.

- Transparency Testing:

- Assess the robot’s ability to explain its actions or decisions clearly to users.

- Fail-Graceful Behavior Testing:

- Test the robot’s ability to halt operations safely during ethical or operational dilemmas.

8. Standards Compliance Testing

Purpose: Ensure the robot adheres to international safety standards.

Key Standards:

- ISO 10218: Safety requirements for industrial robots.

- ISO/TS 15066: Collaborative robot safety.

- ISO 13482: Personal care robots.

- IEC 61508: Functional safety of electrical systems.

Tests for Certification:

- Conducted by third-party organizations like UL (Underwriters Laboratories), TÜV Rheinland, or CE certification bodies.

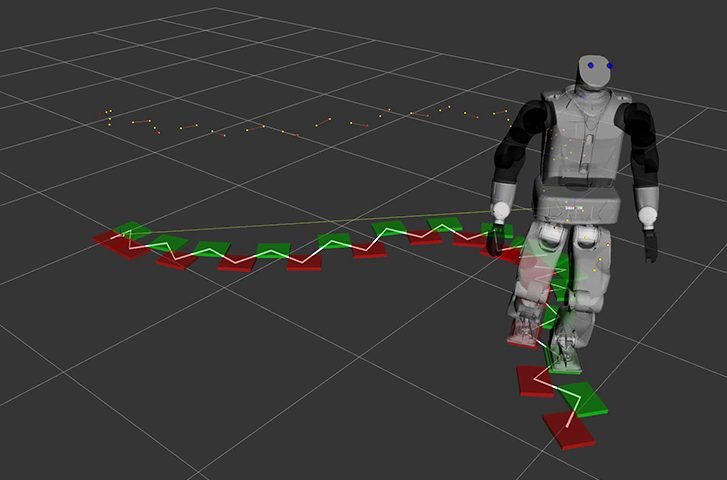

9. Simulated and Field Testing

Purpose: Test the robot in controlled environments and real-world scenarios.

Tests Conducted:

- Simulated Testing:

- Use platforms like Gazebo, Webots, or NVIDIA Isaac Sim to model the robot’s behavior under virtual conditions.

- Field Testing:

- Deploy the robot in real environments (e.g., homes, factories) to evaluate performance and safety during actual use.

10. Documentation and Reporting

Purpose: Maintain records of testing results for compliance and continuous improvement.

Documentation Includes:

- Test protocols and procedures.

- Results of each test, including failures and corrective actions.

- Safety certifications and approvals.

Iterative Testing and Continuous Improvement

Safety testing is not a one-time activity. Robots undergo iterative testing throughout their development and operational lifecycle:

- Perform periodic safety audits to identify and address emerging risks.

- Update software to patch vulnerabilities or enhance features.

- Retest components after repairs or upgrades.

By rigorously testing humanoid robots for safety, manufacturers can ensure their reliability, minimize risks, and foster trust among users.